EVRS

Our evrs® technology is a viable alternative to current processes both ecologically and financially. We have a growing cadre of supporters which needs to be expanded in order to bring these benefits to the whole world. Managing resources in this way, we will move towards the global goal of sustainable one-planet living, leaving something for future generations.

What We Do

Our evrs® process is fully scalable from as little as 1T/Hr upwards to in excess of 10T/Hr per line, operating few or many hours/week, so therefore accords with the “Proximity Principle”, providing solutions at local level, close to the point of production.

We have the Best Possible Environmental Option, (BPEO).

Our processing is sustainable. We have a very low carbon footprint compared to disposal (some 93% reduction over Landfill). Carbon Trust figures put our carbon footprint at less than 1/7 th of that of sending the same materials to landfill.

Having NO discharges to air, to land or water, low noise, and creating no toxic products makes our plant an ideal neighbour!

We focus on residual waste streams others find difficult or impossible, including all plastics, carpet, MDF, sawdust and textiles.

An evrs® materials processor can be operated in the UK under normal B2 (light industry) planning, and only needs a waste licence or environmental permit.

Our technology is financially viable, as we add value to all materials recovered, thereby making operations profitable without dependence on gate fees, as others do.

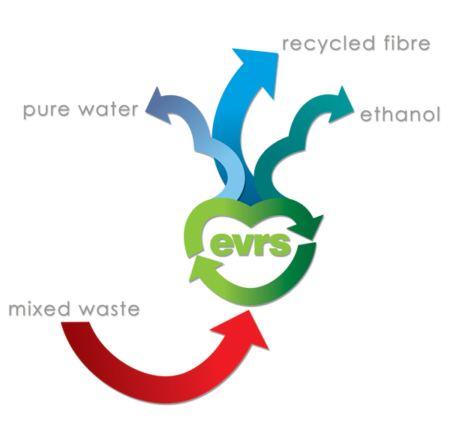

Recovers Resources in residual co-mingled non-hazardous wastes arisings

Produces refined and separated outputs of components, e.g. Cellulose and Polymers, for reuse

Very clean, with NO discharges to air, to land or to water, with almost total recovery and re-use

Existing technologies destroy the fibre, EVRS up-grades it for re-use